Concrete pipe seals, also known as concrete pipe gaskets or concrete pipe joints, are crucial components used to create reliable and leak-proof connections between concrete pipes in various infrastructure and construction applications. These seals are designed to prevent the infiltration and exfiltration of liquids, such as water and sewage, in concrete pipe systems. Concrete pipe seals play a vital role in ensuring the integrity and functionality of drainage and sewer systems, as well as other applications involving concrete pipes. Here, we will explore the key features, types, and common applications of concrete pipe seals:

Key Features of Concrete Pipe Seals:

- Material Composition: Concrete pipe seals are typically made from resilient and durable elastomeric materials, such as rubber compounds or synthetic polymers like EPDM (ethylene propylene diene monomer), neoprene, or natural rubber. These materials offer flexibility, compression, and resistance to environmental factors.

- Sealing Mechanism: Concrete pipe seals are designed to create a secure and watertight seal when pipes are joined together. They function through compression and expansion, ensuring a tight fit as pressure is applied.

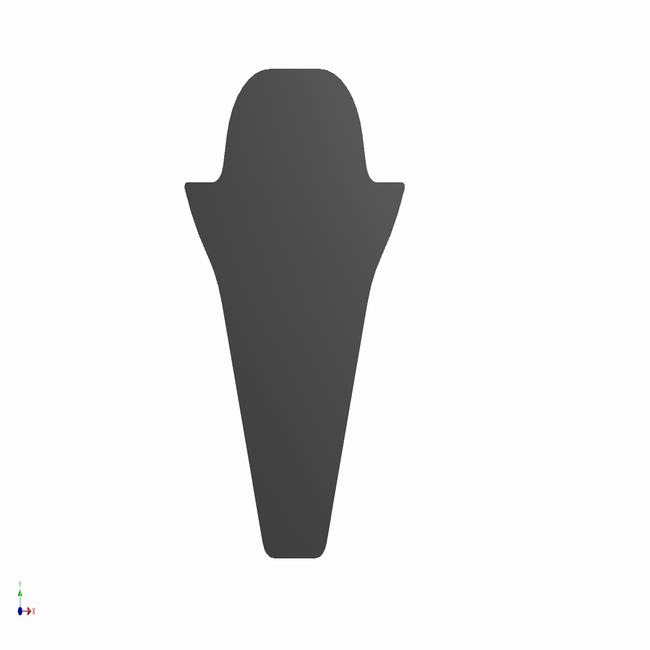

- Customizable Design: These seals are available in various shapes and sizes to accommodate different concrete pipe diameters and joint configurations. Customizable options ensure proper sizing for a specific application.

- Chemical Resistance: Concrete pipe seals are resistant to a range of chemicals and environmental factors, making them suitable for use in sewage and drainage systems.

- Durability: High-quality concrete pipe seals are built to withstand varying temperature conditions, mechanical stress, and long-term exposure to moisture without degrading.

Types of Concrete Pipe Seals:

- Rubber Ring Seals: These seals, also known as flexible or gasketed joints, are placed within a groove or recess on the spigot end of one concrete pipe. When the pipes are joined, the rubber ring compresses to form a watertight seal.

- Mastic Seals: Mastic seals consist of a flexible, waterproof mastic compound applied to the spigot end of the pipe before joining. The compound adheres to the receiving end of the adjacent pipe, creating a sealed joint.

- Compression Gaskets: Compression gaskets are designed to be compressed between the spigot and bell of concrete pipes, creating a watertight seal. They are often used in larger diameter pipes.

Common Applications of Concrete Pipe Seals:

- Sewer and Stormwater Systems: Concrete pipe seals are widely used in sewage and stormwater drainage systems to prevent leakage and contamination of surrounding soil and groundwater.

- Culverts and Bridges: These seals are employed in culvert and bridge construction to ensure the integrity of water drainage systems.

- Irrigation and Drainage: In agricultural applications, concrete pipe seals are used for irrigation and drainage systems to manage water flow efficiently.

- Wastewater Treatment Plants: Concrete pipe seals are critical in wastewater treatment plants to prevent the escape of sewage and hazardous substances.

- Infrastructure Projects: They are used in various infrastructure projects such as road construction, utility installations, and underground pipe networks.

Concrete pipe seals are essential components in the construction and maintenance of drainage and sewer systems, helping to prevent environmental contamination, soil erosion, and infrastructure damage. Properly sealed concrete pipe joints ensure the longevity and reliability of these systems.